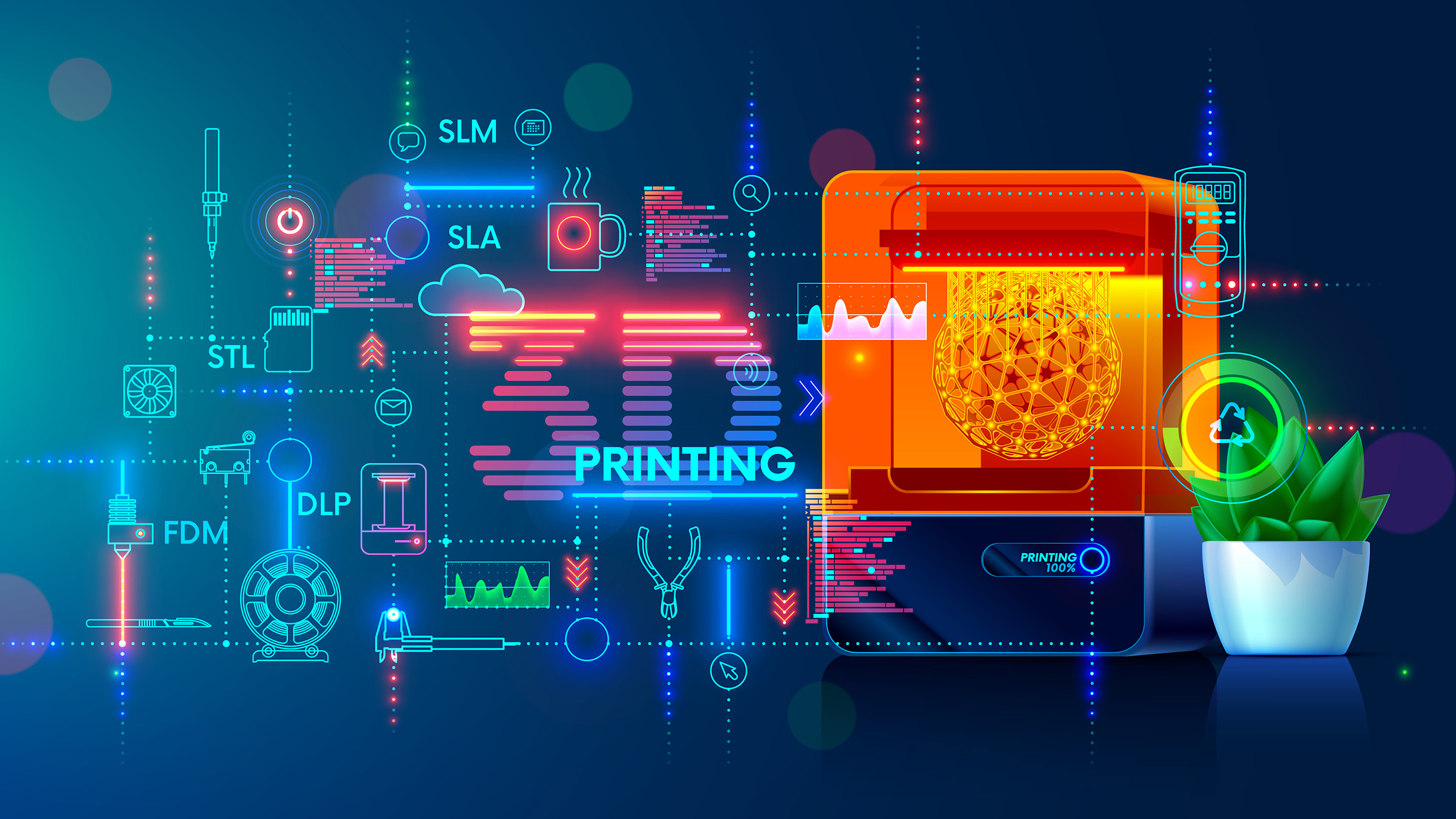

3D Printing & Modeling

Designing and printing objects using CAD software

TinkerCAD, Fusion 360, or SolidWorks to design 3D models.

Rapid prototyping for product development

Cost-effective iteration before mass production

Encourages innovation for startups (custom parts, enclosures)

Laser Cutting & Engraving

Creating precise cuts on wood, acrylic, or cardboard

Create 2D vector designs using software like CorelDRAW or Inkscape

Produces intricate designs quickly for prototypes

Supports IoT hardware casing and structural models

Woodworking & Carpentry

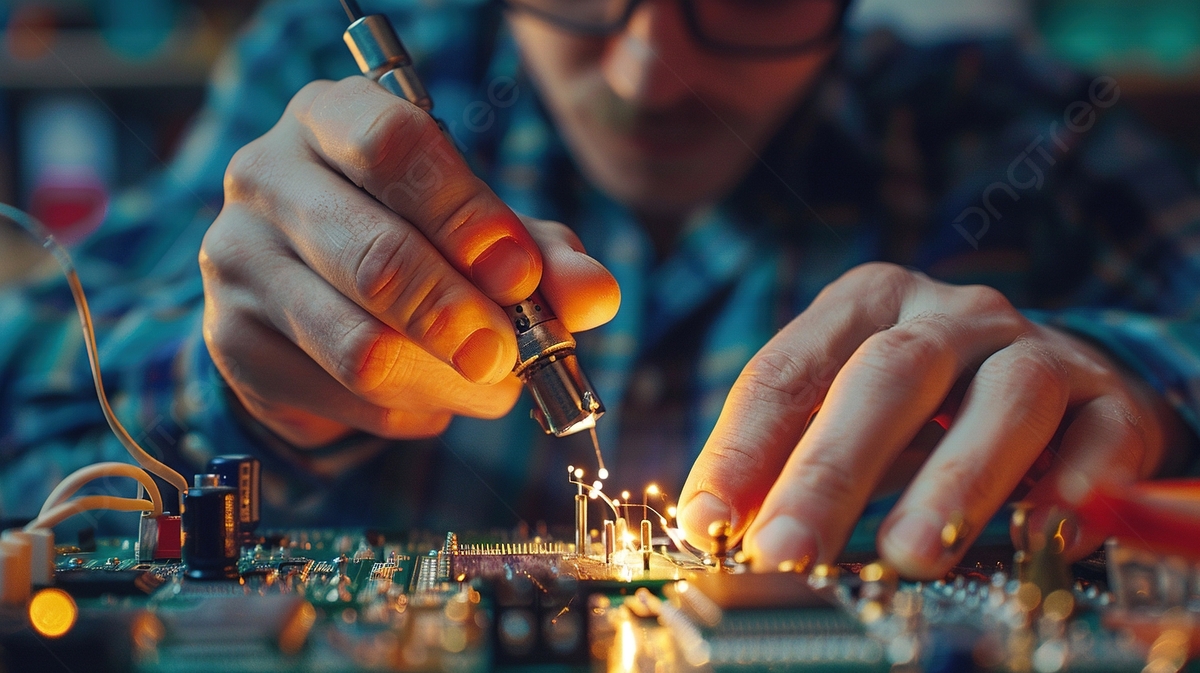

Building physical prototypes with tools

This hands-on activity allows students to build physical objects using traditional tools like saws, hammers, chisels, drills, and clamps.

Projects may include building a shelf, structural frame, or prototype for a product.

Clay Modeling & Sculpting

Hands-on artistic creation

Using clay or similar malleable materials, students sculpt objects that can range from artistic creations to prototype mockups.

It fosters a tactile understanding of shape and form.